FOCUSUN concrete cooling system with flake ice making system

Product Description

Product Description Introduction The cold water tank delivers water to the mixing agitator plant and the flake ice maker (the Focusun flake ice maker is installed inside a 40-ft. container). The capacity varies from 3 to 60 tons daily per unit.

Containerized flake ice maker is for temperate, subtropical and tropical conditions.

Accessories and Additional Equipment

Containerized automatic Ice Storages

Ice delivery (screw and belt conveyors and blowing systems)

Weighing systems

Intermediate holding hoppers (day tanks)

Prefabricated steel frames for the support of the Containerized and Mobile Ice Storages with or without integrated and insulated cold water tank

Prefabricated steel frames for the support of the Containerized and Mobile Ice Storages with integrated ice weighing and ice blowing systems

Containerized Cold or Ice Water Plants

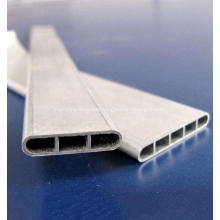

Detailed Images

Detailed Images  Standard execution

Standard execution

One new ISO-container, painted white with air-conditioning, light and aluminum floor

Piston or screw compressors

Electric motors – IP 55 – insulation class F

One evaporative condenser

One or two ice makers with level control

Automatic oil return system

PLC Flow control with indication to ice maker, easy and safe to operate.

Design conditions

Max. ambient temperature:60℃

Wet bulb temperature:30℃

Water inlet temperature:20℃

Ice outlet temperature:-7℃

Refrigerant:R22/R404A

Power supply:380V/50Hz/3P

Running hours flake ice plant:24hours

Requirements on Site

Water (2 bar pressure, 20℃)

electric power supply

adequate foundations

Features 1.Internally-scrapping ice skate can help reduce energy consumption and prevent leakage of refrigerant.2. Stainless steel materials, advanced processing equipment and heat treatment ensure the best heat transfer efficiency.

Features 1.Internally-scrapping ice skate can help reduce energy consumption and prevent leakage of refrigerant.2. Stainless steel materials, advanced processing equipment and heat treatment ensure the best heat transfer efficiency.

3. The design of large water receiving plate can prevent water leaking at the bottom of Evaporator .

4. Photoelectric switch is directly installed in the bottom of evaporator.

5. Direct liquid feeding and dry evaporation is simple, safe and reliable control.

6. Integrated modular equipment installation is convenient for maintenance. Packing & Delivery

Related Products

Flake ice machine 91.8% Response Rate Block Ice Machine 91.8% Response Rate Cube Ice Machine 91.8% Response Rate Our Company Focusun Refrigeration Focusun dedicates itself into researching and developing advanced refrigeration technology. We mainly design and manufacture Tube Ice Machine, block ice machine, flake ice machine, cube ice machine, Plate Ice Machine, Slurry Ice Machine, Water chiller, Vacuum cooler , Concrete cooling system, automatic ice storage system, dynamic ice storage system, snow making system, ice crusher and all kinds of cold rooms.

Flake ice machine 91.8% Response Rate Block Ice Machine 91.8% Response Rate Cube Ice Machine 91.8% Response Rate Our Company Focusun Refrigeration Focusun dedicates itself into researching and developing advanced refrigeration technology. We mainly design and manufacture Tube Ice Machine, block ice machine, flake ice machine, cube ice machine, Plate Ice Machine, Slurry Ice Machine, Water chiller, Vacuum cooler , Concrete cooling system, automatic ice storage system, dynamic ice storage system, snow making system, ice crusher and all kinds of cold rooms.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

* Training how to install the machine, training how to use the machine. * Engineers available to service machinery overseas. Certifications

Certifications  Contact us if you need more details on concrete cooling system. We are ready to answer your questions on packaging, logistics, certification or any other aspects about concrete cooling、concrete cooling way. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on concrete cooling system. We are ready to answer your questions on packaging, logistics, certification or any other aspects about concrete cooling、concrete cooling way. If these products fail to match your need, please contact us and we would like to provide relevant information.

Containerized flake ice maker is for temperate, subtropical and tropical conditions.

Accessories and Additional Equipment

Containerized automatic Ice Storages

Ice delivery (screw and belt conveyors and blowing systems)

Weighing systems

Intermediate holding hoppers (day tanks)

Prefabricated steel frames for the support of the Containerized and Mobile Ice Storages with or without integrated and insulated cold water tank

Prefabricated steel frames for the support of the Containerized and Mobile Ice Storages with integrated ice weighing and ice blowing systems

Containerized Cold or Ice Water Plants

Detailed Images

Detailed Images  Standard execution

Standard executionOne new ISO-container, painted white with air-conditioning, light and aluminum floor

Piston or screw compressors

Electric motors – IP 55 – insulation class F

One evaporative condenser

One or two ice makers with level control

Automatic oil return system

PLC Flow control with indication to ice maker, easy and safe to operate.

Design conditions

Max. ambient temperature:60℃

Wet bulb temperature:30℃

Water inlet temperature:20℃

Ice outlet temperature:-7℃

Refrigerant:R22/R404A

Power supply:380V/50Hz/3P

Running hours flake ice plant:24hours

Requirements on Site

Water (2 bar pressure, 20℃)

electric power supply

adequate foundations

Features 1.Internally-scrapping ice skate can help reduce energy consumption and prevent leakage of refrigerant.2. Stainless steel materials, advanced processing equipment and heat treatment ensure the best heat transfer efficiency.

Features 1.Internally-scrapping ice skate can help reduce energy consumption and prevent leakage of refrigerant.2. Stainless steel materials, advanced processing equipment and heat treatment ensure the best heat transfer efficiency.3. The design of large water receiving plate can prevent water leaking at the bottom of Evaporator .

4. Photoelectric switch is directly installed in the bottom of evaporator.

5. Direct liquid feeding and dry evaporation is simple, safe and reliable control.

6. Integrated modular equipment installation is convenient for maintenance. Packing & Delivery

Flake ice machine 91.8% Response Rate Block Ice Machine 91.8% Response Rate Cube Ice Machine 91.8% Response Rate Our Company Focusun Refrigeration Focusun dedicates itself into researching and developing advanced refrigeration technology. We mainly design and manufacture Tube Ice Machine, block ice machine, flake ice machine, cube ice machine, Plate Ice Machine, Slurry Ice Machine, Water chiller, Vacuum cooler , Concrete cooling system, automatic ice storage system, dynamic ice storage system, snow making system, ice crusher and all kinds of cold rooms.

Flake ice machine 91.8% Response Rate Block Ice Machine 91.8% Response Rate Cube Ice Machine 91.8% Response Rate Our Company Focusun Refrigeration Focusun dedicates itself into researching and developing advanced refrigeration technology. We mainly design and manufacture Tube Ice Machine, block ice machine, flake ice machine, cube ice machine, Plate Ice Machine, Slurry Ice Machine, Water chiller, Vacuum cooler , Concrete cooling system, automatic ice storage system, dynamic ice storage system, snow making system, ice crusher and all kinds of cold rooms. Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to install the machine, training how to use the machine. * Engineers available to service machinery overseas.

Certifications

Certifications  Contact us if you need more details on concrete cooling system. We are ready to answer your questions on packaging, logistics, certification or any other aspects about concrete cooling、concrete cooling way. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on concrete cooling system. We are ready to answer your questions on packaging, logistics, certification or any other aspects about concrete cooling、concrete cooling way. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Concrete cooling system

Premium Related Products

Other Products

Hot Products

CACR-1 Controlled Atmosphere Cold Storage Room With Competitive PriceSolar Mobile Cold Room PriceGood Price Brand New 20ft Reefer ContainerCold Storage for Milk Egg Banana Potato ProductStorage Refrigeration Freezing Rooms for Fruits and VegetablesFood nitrogen gas generatorIndustrial PSA Nitrogen Generator Gas EquipmentHigh Speed 10 Ton Winch For Promotional PriceMade in China Good Quality Anchor Winch5 Ton On High Speed Electric Winch For SaleHigh Purity 95-99.9995% Industrial PSA Nitrogen GenetatorCompetitive Price Electric High Speed Windlass99.9995% HIGH PURITY INDUSTRY NITROGEN MAKING MACHINE GENERATOR PRICE2017 New Mini Cold Storage Equipment For Cold Room By Tianjin OEM2017 New Hot Sales CA Cold Storage Room With Atmosphere Control System By Tianjin OEM China With ISO9001Industrial High Purity 97%~99.9995% PSA Nitrogen Generator Price