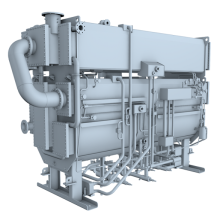

FWC-180 FOCUSUN concrete cooling containerized water chiller system

Product Description

Wet-bulb temperature: 30°C

Water-in temperature : 45°C

Water-out temperature: 0.5°C .

Power supply: 3P/380V/50Hz

Running time: 24hours

Refrigerant: R22/R404A Focusun Water Chiller Stable Performance: imported famous brand compressors with internal security protection, low noise, energy saving and durable. Leading technology: fault-alarm, self-check, signal output and different temperature supervision & control units are connected with the main control system. High EER: different stage cooling can be customized so as to improve the energy-efficiency ratio. High precision: imported high accurate digital display temperature controller can control temperature with high accuracy. Safe and stable: components imported from famous suppliers ensure safe working condition and long service life. Easy maintenance: static-free spraying plastic shell with European design brings elegant appearance and easy user experience. Compressor's continuative energy regulation can adjust the refrigeration capacity of compressors in terms of water outlet temperature. Electronic expansive liquid feeding can accurately control the water level according to the air return pressure and temperature. Products images

An evaporative condensing system is superior to common air-cooled systems due to considerable differences in condensing pressures and temperatures.

An evaporative condensing system is superior to common air-cooled systems due to considerable differences in condensing pressures and temperatures.  We use semi-hermetic compressors made by “BITZER”, or “BOCK" the world famous German manufacturer, to make sure that our customers not only get one of the most reliable compressors in the world but also receive proper service and spare parts everywhere and at any given time.

We use semi-hermetic compressors made by “BITZER”, or “BOCK" the world famous German manufacturer, to make sure that our customers not only get one of the most reliable compressors in the world but also receive proper service and spare parts everywhere and at any given time.  Our chillers are assembled in our new and latest installation facilities by the most experienced refrigeration technicians inside of a 20-ft or 40-ft container. This container is painted white on the inside and outside and equipped with lighting and an air-conditioning unit. Therefore the doors of the container can be kept closed. This avoids that dust and humidity enter the machinery container. We use brand new containers only. The floor of the container inside is layed with chequered aluminium sheets, to avoid rust build-up on the floor.

Our chillers are assembled in our new and latest installation facilities by the most experienced refrigeration technicians inside of a 20-ft or 40-ft container. This container is painted white on the inside and outside and equipped with lighting and an air-conditioning unit. Therefore the doors of the container can be kept closed. This avoids that dust and humidity enter the machinery container. We use brand new containers only. The floor of the container inside is layed with chequered aluminium sheets, to avoid rust build-up on the floor.The ice water plant is assembled, piped, wired and pressure tested completely in our factory, prior to shipment.

Once power and water have been connected, the plant is ready for operation. All safety and control devices are properly adjusted so that the installation of the plant can be done within one day including commissioning. The same applies for the dismantling of the plant. Just connect our plant to the water and power supply as well as to the insulated cold water tank on site and the plant is ready to run. This is also very important for contractors who are changing their site quite frequently. Up to a daily production of 180 m3 cold water, they are installed inside of 20-ft. containers corresponding to a daily concrete production between 200 and 1400 m3. Up to a daily production of 450 m3 cold water, they are installed inside of 40-ft. containers corresponding to a daily concrete production between 1400 and 2800 m3 depending on the actual water inlet temperature and the possible addition of water. Models: (Below models are standard small water chillers)

Once power and water have been connected, the plant is ready for operation. All safety and control devices are properly adjusted so that the installation of the plant can be done within one day including commissioning. The same applies for the dismantling of the plant. Just connect our plant to the water and power supply as well as to the insulated cold water tank on site and the plant is ready to run. This is also very important for contractors who are changing their site quite frequently. Up to a daily production of 180 m3 cold water, they are installed inside of 20-ft. containers corresponding to a daily concrete production between 200 and 1400 m3. Up to a daily production of 450 m3 cold water, they are installed inside of 40-ft. containers corresponding to a daily concrete production between 1400 and 2800 m3 depending on the actual water inlet temperature and the possible addition of water. Models: (Below models are standard small water chillers) Item | Unit | ICW-4-35-10 | ICW-6-35-10 | ICW-12-35-10 | ICW-16-35-10 | |

|---|---|---|---|---|---|---|

| Power Supply | V/P/Hz | 380V/3P/50Hz | 380V/3P/50Hz | 380V/3P/50Hz | 380V/3P/50Hz | |

| Refrigerant | – | R22/R404A | R22/R404A | R22/R404A | R22/R404A | |

| Standard Water Flow Rate | t/24h | 3 | 6 | 12 | 16 | |

| Cooling Way | Air-cooling | Air-cooling | Air-cooling | Air-cooling | ||

| Operation Condition | Ambient Temperature | ℃ | 40 | 40 | 40 | 40 |

| Water Supply Temperature | ℃ | 35 | 35 | 35 | 35 | |

| Water Outflowing Temperature | ℃ | 10 | 10 | 10 | 10 | |

| Compressor | Manufacturer | Copeland | Copeland | Copeland | Copeland | |

| Evaporating Temperature | ℃ | 5 | 5 | 5 | 5 | |

| Condensing Temperature | ℃ | 48 | 48 | 48 | 48 | |

| Cooling Capacity | kw | 5.03 | 7.82 | 16.6 | 22 | |

| Operating Power | kw | 1.5 | 2.21 | 4.58 | 5.86 | |

| Compressor COP/EER | kw/kw | 3.35 | 3.54 | 3.62 | 3.75 | |

| Model | ZR22K3E-TFD | ZR34K3E-TFD | ZR72KCE-TFD | ZR94KCE-TFD | ||

| Compressor Type | Vortex Compressor | Vortex Compressor | Vortex Compressor | Vortex Compressor | ||

| Operating Power | Water Pump | kw | 0.125 | 0.15 | 0.37 | 0.55 |

| Condenser Fan | kw | 0.7 | 1.1 | 1.5 | 1.5 | |

| Compressor Power | kw | 1.5 | 2.21 | 4.58 | 5.86 | |

| Total Running Power | kw | 2.325 | 3.46 | 6.45 | 7.91 | |

| Installment Power | kw | 3 | 5 | 10 | 12 | |

| Dimension | Contour Dimension | L×W×H(mm) | 1200×800×850 | 1200×1200×850 | 1600×1200×1000 | 1600×1400×1000 |

| Water Inlet Dimension | Inch | 0.5 | 0.5 | 0.5 | 0.5 | |

| Water Outlet Dimension | Inch | 0.5 | 0.5 | 0.5 | 0.5 | |

| Water Tank | Material | SUS304 | SUS304 | SUS304 | SUS304 | |

| Contour Dimension | L×W×H(mm) | 1200×400×400 | 1200×500×500 | 1200×500×1000 | 1200×500×1000 | |

| Volume | L | 192 | 200 | 600 | 600 | |

| Net Weight | Water Chiller | kg | 268 | 286 | 465 | 674 |

| Water Supply Pressure Requirement | bar | 2~4 | 2~4 | 2~4 | 2~4 | |

| Item | Unit | ICW-4-35-10 | ICW-6-35-10 | ICW-12-35-10 | ICW-16-35-10 | |

| Power Supply | V/P/Hz | 380V/3P/50Hz | 380V/3P/50Hz | 380V/3P/50Hz | 380V/3P/50Hz | |

| Refrigerant | R22 | R22 | R22 | R22 | ||

| Standard Water Flow Rate | t/24h | 20 | 20 | 20 | 20 | |

| Cooling Way | Air-cooling | Air-cooling | Air-cooling | Air-cooling | ||

| Operation Condition | Ambient Temperature | ℃ | 40 | 40 | 40 | 40 |

| Water Supply Temperature | ℃ | 35 | 35 | 35 | 35 | |

| Water Outflowing Temperature | ℃ | 10 | 10 | 10 | 10 | |

| Compressor | Manufacturer | Copeland | Copeland | Copeland | Copeland | |

| Evaporating Temperature | ℃ | 5 | 5 | 5 | 5 | |

| Condensing Temperature | ℃ | 48 | 48 | 48 | 48 | |

| Cooling Capacity | kw | 29.3 | 33.4 | 42.9 | 69.8 | |

| Operating Power | kw | 7.7 | 8.76 | 11.9 | 19.25 | |

| Compressor COP/EER | kw/kw | 3.81 | 3.81 | 3.61 | 3.63 | |

| Model | ZR125KCE-TFD | ZR144KCE-TFD | ZR190KCE-TFD | ZR310KCE-TFD | ||

| Compressor Type | Vortex Compressor | Vortex Compressor | Vortex Compressor | Vortex Compressor | ||

| Operating Power | Water Pump | kw | 0.55 | 0.75 | 0.75 | 1 |

| Condenser Fan | kw | 2.2 | 3 | 3.5 | 4.5 | |

| Compressor Power | kw | 7.7 | 8.76 | 11.9 | 19.25 | |

| Total Running Power | kw | 10.45 | 12.51 | 16.15 | 24.75 | |

| Installment Power | kw | 15 | 18 | 21 | 30 | |

| Dimension | Contour Dimension | L×W×H(mm) | 1800×1600×1000 | 2500×1600×1000 | 2500×1600×1000 | 4200×1800×1000 |

| Water Inlet Dimension | Inch | 0.75 | 0.75 | 0.75 | 1 | |

| Water Outlet Dimension | Inch | 0.75 | 0.75 | 0.75 | 1 | |

| Water Tank | Material | SUS304 | SUS304 | SUS304 | SUS304 | |

| Contour Dimension | L×W×H(mm) | 1200×500×1000 | 1200×600×1200 | 1200×600×1200 | 1500×1000×1200 | |

| Volume | L | 600 | 864 | 864 | 1800 | |

| Net Weight | Water Chiller | kg | 824 | 1025 | 1168 | 1924 |

| Water Supply Pressure Requirement | bar | 2~4 | 2~4 | 2~4 | 2~4 | |

Model | -- | FWC36 | FWC60 | FWC72 | FWC96 | FWC120 | FWC180 | FWC240 | FWC360 | FWC480 |

Daily capacity | Tons/day | 36 | 60 | 72 | 96 | 120 | 180 | 240 | 360 | 480 |

Ice water flow | Tons/hr | 1.5 | 2.5 | 3 | 4 | 5 | 7.5 | 10 | 15 | 20 |

Necessary Refigeration | KW | 74.4 | 124.0 | 148.8 | 198.3 | 124.0 | 124.0 | 124.0 | 124.0 | 124.0 |

Total electric power | KW | 22.5 | 36.8 | 41.6 | 56.7 | 66.1 | 97.6 | 121.6 | 196.8 | 254.9 |

COP | KW/KW | 3.7 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 | 3.8 |

Container Specification | -- | 20' | 20' | 20' | 20' | 20' | 20' | 40' | 40' | 40' |

Water tank volume | m3 | 12 | 20 | 24 | 32 | 40 | 60 | 80 | 120 | 160 |

COMBINED CONCTE BATCHING PLANTS INCLUDES: 1- flake ice plant with water : 2- A capacity of 30~60 tons flake ice within 24 hours 3- One steel construction ,for ice storage 4- One automatic ice rake system 5- One ice discharge conveyor screw left/right operation 6- Tow conveyor screw for discharge of the flake ice from the ice storage to concrete plant length adjustable 12 to 25meter 7- Weighing device Other Products: Tube Ice Plant Block Ice Plant Snow-making System Slurry Ice Plant Please contact me any time! Wendy Tang Export Sales Co-ordiantor Focusun Refrigeration (Shanghai) Corporation

COMBINED CONCTE BATCHING PLANTS INCLUDES: 1- flake ice plant with water : 2- A capacity of 30~60 tons flake ice within 24 hours 3- One steel construction ,for ice storage 4- One automatic ice rake system 5- One ice discharge conveyor screw left/right operation 6- Tow conveyor screw for discharge of the flake ice from the ice storage to concrete plant length adjustable 12 to 25meter 7- Weighing device Other Products: Tube Ice Plant Block Ice Plant Snow-making System Slurry Ice Plant Please contact me any time! Wendy Tang Export Sales Co-ordiantor Focusun Refrigeration (Shanghai) Corporation Add: No. 7755, Zhongchun Rd, Minhang District

Shanghai China 201413

Tel: +86-21-51089946*808

Fax: +86-21-5754-4199

Phone: +86-158-2191-2409

www.focusun.com

www.chinaicemachine.com Contact us if you need more details on water chiller. We are ready to answer your questions on packaging, logistics, certification or any other aspects about water chiller system、concrete. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water chiller

Premium Related Products